DIGITAL CONTROL PANEL IS INCLUDED. HEATING RESISTOR CAN BE ADDED SEPARATELY DEPENDING ON YOUR NEEDS.

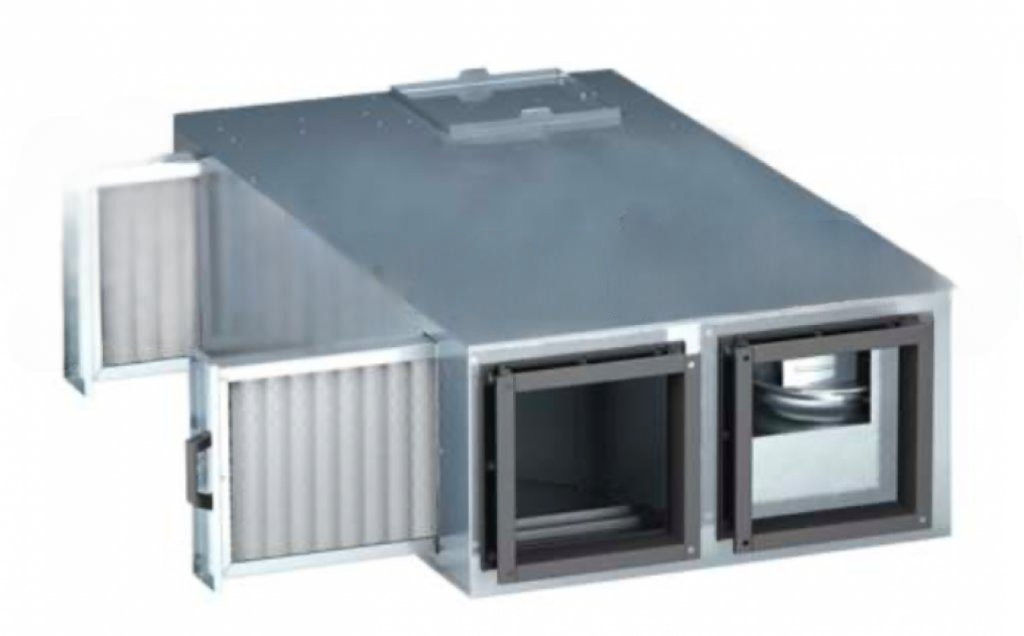

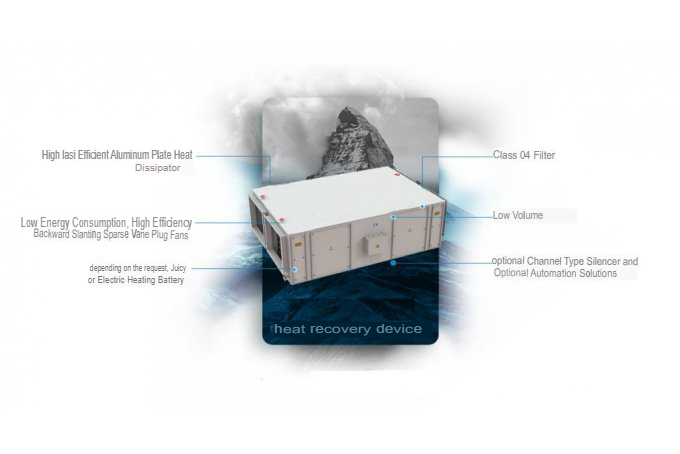

- heat recovery units have been specially developed to provide the high indoor air quality required by closed spaces while minimizing energy consumption.

- It conditions the fresh air by using the sensible and latent heat energy of the exhausted air. The energy of the exhausted air is transferred to the fresh air by a cellulosic type energy recovery exchanger.

- Due to the feature of the cellulosic type heat exchanger, moisture transfer also occurs at the same time.

| Technical Specifications |

| Model |

IGC 450 |

| Transfer |

2,100 rpm |

| Pressure |

325 pa |

| Flow |

4,000 m3/h |

| Voltage |

230V |

| Motor power |

2 X 750W |

| Weight |

195 kg |

| Dimensions (LxWxH) |

1,800mm X 1,200mm X 650mm |

| Sound |

78dB |

| Heat Exchanger Type |

PP 600X600 |

| Product Advantages |

- It provides the necessary fresh air and improves indoor air quality.

- Exhausts low quality air from indoor environment.

- It conditions the fresh air with both sensible and latent heat energy of the exhaust air.

- It increases the humidity of the air supplied inside by transferring the moisture of the exhausted air to the fresh air in winter.

- In summer, it reduces the humidity of the air given in by transferring the humidity of the fresh air to the exhaust air.

- It filters the outside air and brings it inside.

- Thanks to its bypass feature, it provides natural cooling during transition seasons.

- Thermal efficiency up to 80 percent

- Low energy consumption

- Energy transfer

- Moisture transfer

- Ventilation as needed

- Low noise level

- Automatic natural cooling

- Compact and slim design

- Easiest access and maintenance to all components

- Optionally, a heating resistance can be installed.

|

| Usage areas |

- Offices

- Hotel rooms

- Performance centers

- Cafeterias

- Dormitories

- Classes

- Private teaching institutions

- Shopping Malls

|

Reviews

There are no reviews yet.