Description

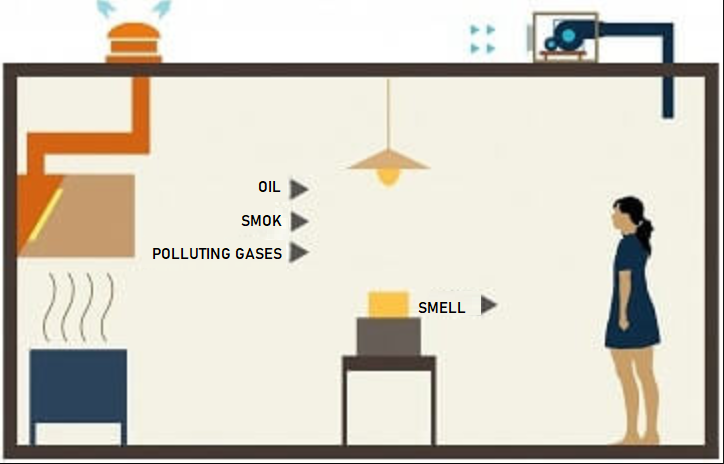

It is necessary to remove the odor, pollutant particles and moisture that arise during cooking in kitchens from the environment and to provide the necessary indoor air quality for employees. The ventilation and air conditioning system needed to ensure air quality for the operations carried out in the kitchen, to prevent the exhaust air discharged from polluting the environment, and to ensure the continuity of health conditions is called kitchen ventilation and air conditioning.

Kitchen ventilation and air conditioning systems;

1. Pollution of the air in the kitchen due to gaseous combustion products, oil particles and odor,

2. Hygiene requirement of indoor air,

3. Serious heat generation through convection and radiation,

4. Significant humidity formation due to preparation and washing of food,

5. It is necessary in commercial kitchens due to reasons such as renewing the air by replacing the indoor air with outdoor air and maintaining the determined room temperatures.

When we calculate the balance sheet of heat and humidity gains and losses in the kitchen, we see that in many applications it gives positive results throughout the year, that is, it is more than necessary and has disturbing and risky effects. Because of this feature, we can consider excessive heat and humidity in the kitchen as pollutants by another definition. Preventing such pollution is possible by reducing the heat and humidity emitted to the environment. Reducing the humidity and temperature in the environment is done by ventilation or cooling processes.

As can be seen from all this, in order to prevent pollution in the kitchen environment;

– Ventilation

– Filtering

– Cooling operations must be carried out.

Recovery and cleaning of pollutants after they spread into the environment; It is much more difficult and costly than collecting and cleaning it without falling apart. For this reason, hood systems are used to remove pollutants from the environment before they disperse.

Air Velocity in the Kitchen

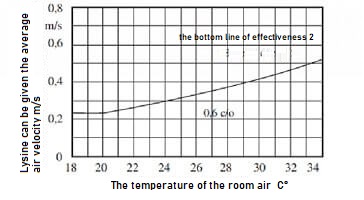

Air velocity in the comfort zones of the kitchen is related to the room air temperature, the turbulence of the flow and the insulation value of clothing. The limits given in the DIN EN 13779 Standard must be maintained up to the flow rate of 35 m3/(m2h) depending on the area. In case of higher air flow rates (flow rates) per unit of area, the limit curve given in Figure 7 must not be exceeded. Measurements in the workplace should be made at a height of 1.7 m from the floor.

Figure 7 Average Allowable Air Velocity as a Function of Room Temperature

In case of laminar flow, the velocity at a height of 0.1 m above the floor should not exceed 0.2 m/s. This value is valid for a room temperature of 20˚C and a distance of 0.8 m from the air terminal unit. When the distance between the workplace and the air terminal unit is greater, higher air velocities can be allowed at a distance of 0.8 m from the air terminal unit.

Reviews

There are no reviews yet.