Description

Their height is 380-500 mm. Air Handling Units are suitable for placement in suspended ceilings. It is manufactured from European painted PVC sheet with a 3-speed monophase motor with capacities between 1000 m3/h and 5000 m3/h, 1000 kcal/h-25,000 kcal/h. It can be painted with electrostatic oven paint upon request. 20 and 25-30 mm depending on acoustic and thermal needs. It is manufactured by injecting 40 kg/m3 density polyurethane foam or placing isoglass sheet between thick PVC sheets.

| Product Advantages | |

|

|

| Usage areas | |

|

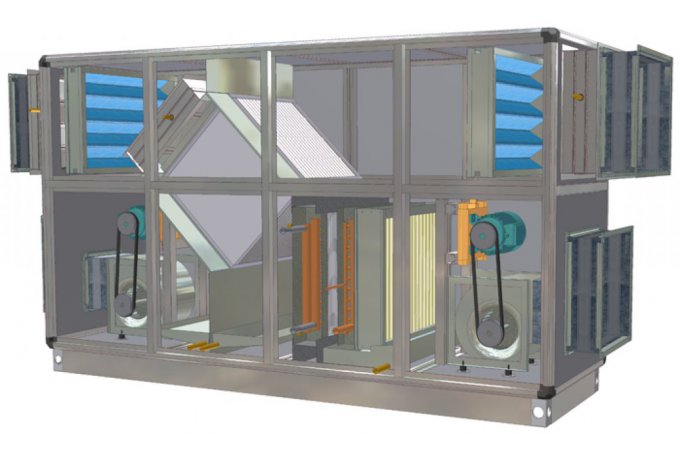

DX BATTERY AIR HANDLING UNITS

Our DX battery air handling units have the feature of cooling without the need for a chiller and heating without the need for a hot water boiler, thanks to the synchronized VRF outdoor unit.

Our DX air handling units, consisting of an air handling unit and VRF outdoor unit.

Features of DX Air Handling Units:

1. Our DX air handling units are produced between 1800 and 25000 m³/h air flow rate and 14-224 kW cooling capacity.

Energy savings are achieved with the highly efficient heat recovery rotor or plate recuperator in our 2.DX air handling units.

Our 3.DX air handling units have a rock wool insulated panel structure with a thickness of 42 mm and a density of 50 kg/m³.

Our 4.DX air handling units have all the necessary safety and warning signs and capacity information labels. The fans used in our 5.DX power plants have a plug

feature directly coupled to the motor shaft, suitable for control with a frequency inverter . It can be used in 92% efficient EC motor plug fans.

In our 6.DX air handling units, fan motor powers are selected by taking dirty filter pressures into consideration.

Our 7.DX air handling units have internal MCC (Magnetic Control Center) and DDC (Direct Digital Control) panels with appropriate protection class. 8.In our DX air handling units, there is an emergency safety button

in addition to the MCC and DDC panels .

9.The compact switch that separates the device from the electrical network during emergency intervention is available outside the device.

In our 10.DX Air Handling Units, EEV (electronic expansion valve) and temperature sensors are mounted inside the device during the manufacturing phase, protected from external weather conditions.

When the VRF unit connected to our 11.DX air handling units is defrosted, the control system of the air handling unit goes into standby mode without alarming.

12.DX batteries are selected to be able to operate as cooling (evaporator) in summer and heating (condenser) in winter.

In our 13.DX air handling units, sight glass and siphon accessories are provided.

Optionally, a frequency inverter is used for the AC motor fan in our 15.DX air handling units. Frequency inverters to be used in motor control have high EMC filtering feature.

The plug fans used in our 16.DX air handling units can control the air flow rate by calculating the differential pressure with the internal inverter.

17.Pressure changes such as filter pollution in the air flow passing over the DX battery are controlled.

Optionally in our 18.DX air handling units, microprocessor controller ModBUS RTU etc. in the DDC panel. It has the ability to communicate with at least one communication protocol.

19.In our DX air handling units, an optional microprocessor controller has been programmed with software suitable for the operating logic of DX systems. Critical operating scenarios with mutual alarm controls such as Hot Start, Defrost Time, Defrost Cycle etc. are recorded in the software of the DX air handling unit automation. In this way, maximum system security measures are provided.

Optionally in our 20.DX air handling units, damper motors, differential pressure sensors, temperature and humidity sensors, CO2 or CO/VOC sensors, 3-way valve bodies, proportional valve actuators, frost protection, interior lighting, etc., all field sensing and control equipment in the air handling unit. It is mounted on.

Reviews

There are no reviews yet.