Description

Their height is 380-500 mm. Air Handling Units are suitable for placement in suspended ceilings. It is manufactured from European painted PVC sheet with a 3-speed monophase motor with capacities between 1000 m3/h and 5000 m3/h, 1000 kcal/h-25,000 kcal/h. It can be painted with electrostatic oven paint upon request. 20 and 25-30 mm depending on acoustic and thermal needs. It is manufactured by injecting 40 kg/m3 density polyurethane foam or placing isoglass sheet between thick PVC sheets.

| Product Advantages | |

|

|

| Usage areas | |

|

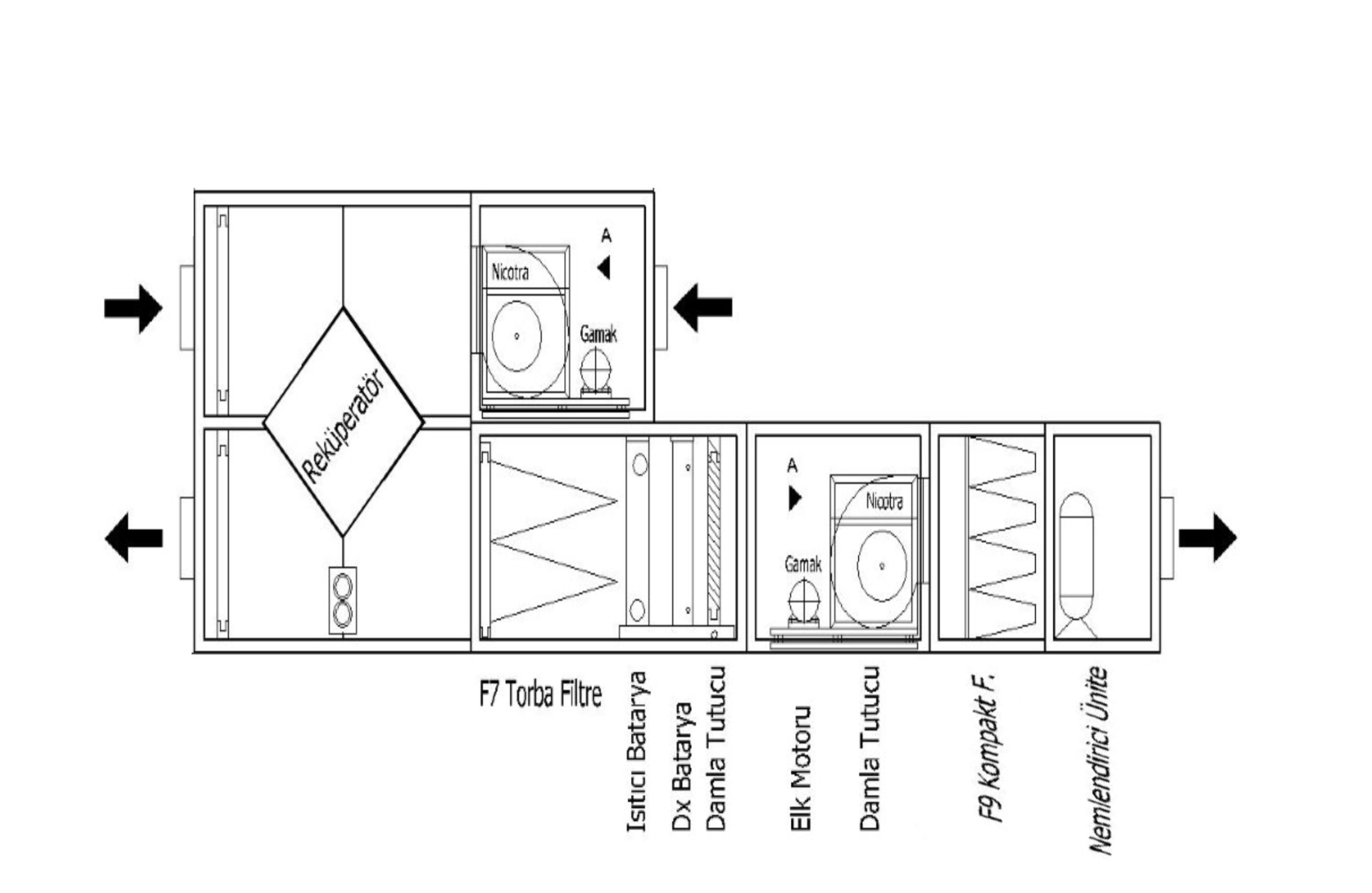

CELL STRUCTURE

The panels of Air Conditioning Hygienic Air Handling Units are manufactured from inner wall 304 Quality Stainless Steel Sheet.

The outer wall of the panels is made of painted 0.7 mm galvanized sheet metal. 30 mm Rockwool is placed between the two sheets.

The frame on which the panels are mounted is made of aluminum edge and intermediate profiles.

Profiles are joined to each other with aluminum casting corners.

Engine, Filter etc. on the power plant. There is an intervention cover that opens and closes at maintenance points.

There is a sight glass on the doors for visual control.

FILTRATION

3-stage Filter is Used in Hygienic Air Handling Units in accordance with EN1882 Standards.

1st Stage G4 Class Panel Filter

2nd Stage F7 Class Bag Filter

Stage 3 G9 Class Compact Filter

The number of filters varies depending on the air flow rate.

H13 Class Filter can be added additionally if desired.

FANS AND MOTORS

Nicotra brand Radial Fans are used as standard in Air Conditioning Hygienic Air Handling Units.

Engines are Gamak Brand. The Motor-Fan group is grouped with the Belt-Pulley system.

Thus, high efficiency is achieved from the fan and the device has a longer lifespan.

While maintenance costs are reduced, periodic inspection and maintenance are easier than direct drive fans

HEAT RECOVERY

Hygienic air handling units are optionally produced with heat recovery.

In addition, energy savings are achieved with 30% efficiency.

BATTERIES

Heating and cooling coils according to the needs of the space in Air Conditioning Hygienic Air Handling Units;

It is placed in the device as water, steam or Dx type depending on the infrastructure of the building.

OTHER EQUIPMENT

In air conditioning Hygienic Air Handling Units, optionally Control panel, Damper servomotors, fFrk pressure sensors, Pollution meter for Filters, etc. equipment can be used.,

Reviews

There are no reviews yet.